The Leading Private Jet Engine Manufacturers: An Overview and Trends

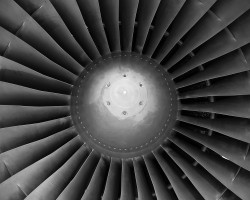

In the demanding world of business aviation, a jet’s performance depends on more than just its airframe, interior design, or avionics. At the heart of every aircraft lies its engine, a key factor influencing cruising speed, range, cabin noise levels, fuel consumption, operating costs, and environmental impact. As operators, owners, and regulators alike raise the bar, engine manufacturers are devoting substantial research and development efforts to create turbines that are ever more reliable, efficient, and eco-friendly.

This article provides an overview of the primary engine manufacturers for private jets. We will explore their flagship product lines, technological innovations, the standout aircraft they power, and current market trends. Our goal: to help you gain a clearer understanding of the issues and selection criteria surrounding engines in the business aviation sector.

The Importance of Engine Choice in Business Aviation

Before delving deeper, it’s worth recalling why engines are such a decisive factor. A high-performance engine ensures greater range, allowing nonstop transcontinental journeys, access to remote airports, and flexible route planning. It also boosts cost-effectiveness by reducing fuel consumption and maintenance expenses. Furthermore, mechanical reliability and spare parts availability are critical for minimizing downtime—an essential concern for business jet operators and private owners.

Environmental considerations are now front and center. New regulations and heightened public awareness push engine manufacturers to design quieter turbines with lower CO₂ emissions and compatibility with sustainable aviation fuels (SAF).

1. Rolls-Royce: Excellence and Heritage in the Service of Innovation

A Historical Pillar of Aeronautical Propulsion

Rolls-Royce embodies British elegance and reliability in aviation. Long renowned for its military and commercial engines, the company has also earned a top spot in the high-end business jet segment. Its turbines provide an optimal combination of power, long range, and controlled noise levels.

Flagship Engines and Notable Aircraft

The BR700 and Pearl series exemplify Rolls-Royce’s technological prowess. The BR710, for instance, powers the Global 5000, a business jet with intercontinental capabilities, while the newly developed Pearl 10X has been selected for the upcoming Falcon 10X, promising unprecedented range. These engines offer reduced fuel burn, streamlined maintenance, and strong thrust, meeting the needs of aircraft designed for ocean-spanning journeys in exceptional comfort.

Toward Greater Environmental Efficiency

Rolls-Royce invests in lighter materials, more efficient compressors, and combustion chambers that lower emissions. The aim: to continuously improve the performance-to-environmental-impact ratio.

2. Pratt & Whitney: North American Innovation for Business Aviation

A Major Player Across All Segments

Pratt & Whitney (P&W) occupies a prominent position in aviation, powering commercial airliners, helicopters, and business jets alike. Its subsidiaries, including Pratt & Whitney Canada, offer a wide range of turbines suited to different market segments.

Engine Families and Varied Integrations

From the PW300 to the PW800, as well as the PW500 and PW600 series, P&W covers a vast array of needs. Dassault Falcons demonstrate this diversity: the Falcon 6X uses a PW812D, while the Falcon 7X and Falcon 8X rely on PW307 engines. Meanwhile, Embraer’s Phenom 100 and Phenom 300 use PW617F and PW535E, respectively—proving P&W’s capability to address demands from large long-range aircraft to light jets.

Cost Optimization and Environmental Responsibility

P&W focuses on improving energy efficiency, reducing noise, and simplifying maintenance. This strategy yields engines that are more durable, fuel-efficient, and easier to service—key advantages for operators seeking both performance and profitability.

3. GE Aviation: The Weight of an Industrial Giant

Expertise Rooted in Commercial Aviation

GE Aviation is globally recognized for its engines used on airliners. In the business jet world, the CF34 series has powered aircraft known for their ruggedness and range like the Challenger 650. These engines are appreciated by operators for their reliability, easy maintenance, and the extensive technical support network that GE provides.

Innovation and Global Support

As a large-scale industrial player, GE Aviation ensures high parts availability and comprehensive technical assistance, streamlining maintenance and minimizing downtime. This support is invaluable to operators looking to extend the life cycle of their aircraft fleets.

4. Honeywell Aerospace: Engineering at the Heart of Business Jet Propulsion

Diversification and Know-How

Honeywell excels in multiple domains—from avionics to cabin management systems—and also shines in business jet propulsion. Its engines stand out for their reliability, strong performance, and adaptability to varied operational requirements.

The HTF7000 Series and TFE731 Turbofans

The HTF7000 series, featured on the Challenger 300, strikes a balance between power, efficiency, and operating costs. Meanwhile, TFE731 engines have powered legendary models like the Learjet 40, admired for its versatility and consistent performance.

Predictive Maintenance and Continuous Innovation

Honeywell focuses on predictive maintenance technologies, component weight reduction, noise reduction, and efficiency improvements—maximizing aircraft availability and operational profitability.

5. Safran Aircraft Engines: Franco-American Synergy Driving Ambition

Toward New Opportunities?

Though Safran faced challenges with its Silvercrest engine—originally intended for certain new business jets—the company remains determined to establish itself in this segment. It is committed to developing quieter, more fuel-efficient turbines compatible with sustainable aviation fuels. By refining its technological solutions, Safran aims to attract OEMs and operators seeking optimized performance, controlled costs, and environmental responsibility. The objective: to help shape the transformation of business aviation and promote the emergence of more virtuous propulsion systems.

6. Williams International: The Specialist in Light Turbofans

A Key Reference for Small Private Jets

Williams International has carved out a niche in the light turbofan market. Its FJ44 series powers aircraft such as the Pilatus PC-24, a highly versatile business jet capable of operating from short runways. This success is rooted in the engines’ efficiency, compactness, and ease of maintenance.

Flexibility and Controlled Costs

Williams engines appeal to operators seeking an optimal balance between reasonable costs, solid performance, and simplified maintenance, thereby contributing to the democratization of business aviation.

Market Trends: Efficiency, Sustainability, and Innovations

Sustainable Aviation Fuels (SAF)

Engine manufacturers are adapting their turbines to run on SAF. Derived from renewable sources, these fuels shrink the carbon footprint without sacrificing performance. Over time, SAF is expected to become a standard in business aviation.

Hybrid or Electric Powerplants

While fully electric jets remain a distant prospect, hybridization is emerging as a promising avenue. By combining gas turbines with batteries, these systems could further reduce fuel consumption, noise, and emissions, all while maintaining a satisfactory range.

Noise Reduction and Predictive Maintenance

Minimizing noise is a major objective for engine makers, benefiting both passenger comfort and the surrounding communities. Simultaneously, predictive maintenance—based on real-time operational data—allows for wear detection, extended maintenance intervals, and lower operating costs.

If you would like to know more about this subject, you should read our blog article on sustainability innovation in private aviation: Sustainability in Private Aviation: How the Industry Is Going Green

Selection Criteria: Assessing Needs and Anticipating the Future

Choosing an engine involves several key considerations:

- Range and Performance: Maximizing nonstop flights to more distant destinations.

- Operating Costs: Assessing fuel consumption, maintenance, parts availability, and technical support.

- Reliability and Technical Assistance: A wide maintenance network and responsive after-sales service reduce downtime.

- Future Compatibility: Ensuring adaptability to SAF, potential technological upgrades, and compliance with environmental regulations.

Conclusion: A Strategic Choice at the Heart of Performance

The engine is central to a private jet’s operational success. Whether you choose Rolls-Royce, Pratt & Whitney, Honeywell, Williams International, or giants like GE and Safran, each manufacturer offers a range of solutions and a unique approach. Operators and owners must weigh their priorities—range, costs, environmental impact, maintenance—and select the engine best suited to their needs.

This sector is undergoing rapid change, driven by environmental imperatives, technological innovation, and the diversity of client demands. In this context, staying informed and comparing options is essential. For more in-depth information, consult the aircraft listings on www.linkinjet.com, contact experts, and keep track of industry developments to make the best possible decision.

+41 22 710 78 00